We Deliver Solutions That

Fuel The World

We have supplied the oil and gas markets for over 100 years. Starting with the innovative extruded outlet header fitting in the 1950s, the finger slug catcher in the 1970s, and continuing recently with vortex separators, we continuously look to serve our customers with unique, reliable, and high-quality solutions.

Defend Our Country

As a critical supplier of products for the defense industry, we take pride in our contribution to the well-being and continued protection of the country.

Explore The Universe

As an early leader in high pressure ASME Section VIII pressure vessel design, we have supported NASA and the aerospace industry for over 75 years.

A Legacy of Reliability

Taylor Forge has established itself as an industry leader with over 100 years of experience supplying equipment to the oil and gas, aerospace, and defense markets. Our unique combination of engineering, manufacturing, and fabrication capabilities makes us a true partner in delivering solutions that protect critical assets in the energy sector. Driven by integrity and quality, TFES continues to expand its reach into new markets while maintaining a cornerstone of excellence for our existing customers.

Engineered to meet your needs

Complex circumstances require thoughtful solutions. Taylor Forge provides equipment for a wide range of roles in storage, separation, and more.

Our Solutions

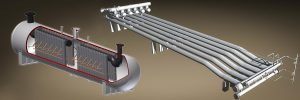

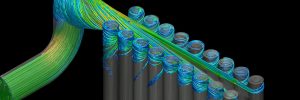

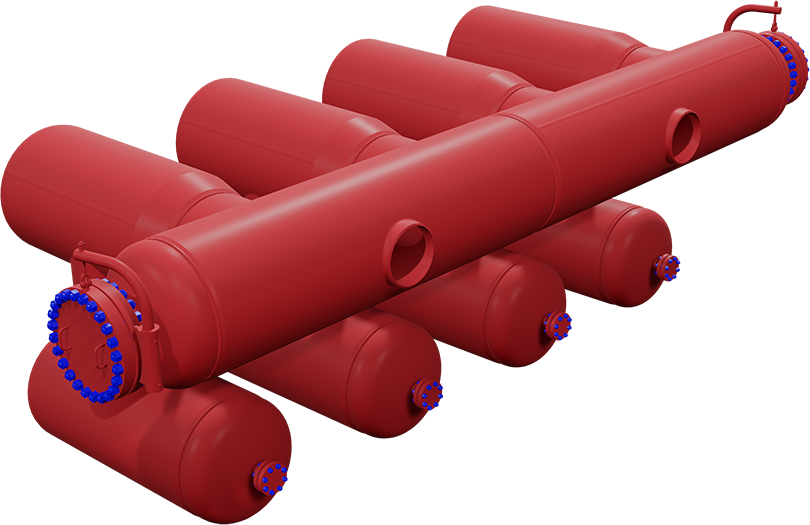

Slug Catcher

Taylor Forge is the industry leader for the design and fabrication of Finger or Harp Style Slug Catchers. With over 50 years of experience, Taylor Forge has the bandwidth to handle the most complex process flows and the materials expertise to the harshest conditions.

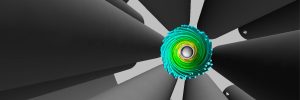

Vortex Separation Technology

The TFES Vortex Separators offer a low maintenance, high performance solution for your filtration and separation needs. Perfect for applications in compressor stations, gas processing facilities, amine plants, and many other process flow streams, vortex or cyclonic separation provides a smaller footprint with advanced design principles as compared to conventional separation technology.

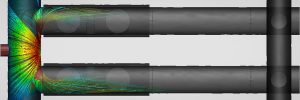

Extruded Outlet Headers and Manifolds

Developed by TFES in the 1950s, Taylor Forge is the foremost leader on extrusion technology and application.

Pressure Vessels

Specializing in high pressure solutions, Taylor Forge has supported the energy, offshore, and aerospace sectors for over 75 year fabricating vessels operating at 15,000psi.

Pig Launchers and Receivers

With capabilities to design and fabricate pigging solutions for pig trap assemblies from 300psi to 20,000psi, Taylor Forge is uniquely suited to support the pipeline industry for piggable launcher and receiver solutions.

Offshore Platform Equipment

With 25 years of specialized high strength low alloy solutions in the high yield offshore sector, Taylor Forge’s capabilities allow its customers to purchase reliable solutions that save weight while not sacrificing quality and longevity.

About Us

Industry Leading Insights

Technical Library