Extruded Outlet Headers

Dimensionally-flexible, reliable fittings

Process Pioneers

Taylor Forge Engineered Systems developed the extrusion process in the 1950s to fill a gap in reduced outlets that the standard and custom tee market couldn’t supply. Extruded headers or extruded manifolds enable butt-welded connections where tees are unavailable and O-Lets are considered unreliable. Predominantly designed according to pipeline codes (B31.8, B31.3, or B31.1), thicknesses are calculated rather than tested to failure, ensuring consistent engineering. Using proprietary in-house carbon steel plate as the base material for pipeline applications, Taylor Forge can easily achieve a wide range of yield strengths and MDMTs (down to -50°F), while maintaining competitive pricing compared to other technologies.

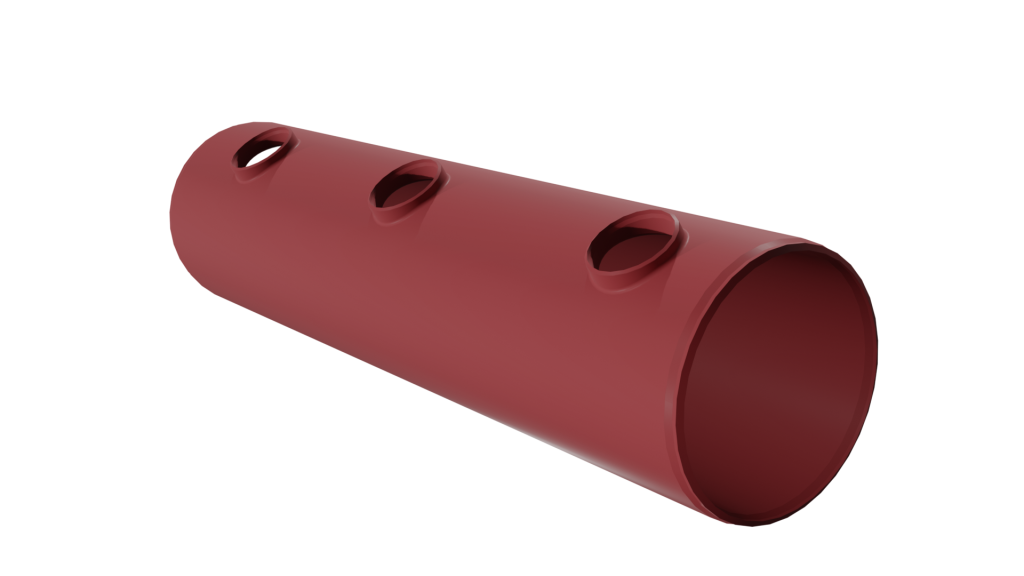

MULTIPLE OUTLET HEADERS

With in-house rolling capabilities up to 13’, Taylor Forge is uniquely positioned to eliminate girth welds in your facilities design.

LOW AND HIGH TEMP, ALLOY FRIENDLY

Taylor Forge Engineered Systems has established itself as an industry leader through decades of innovation, quality, and reliability in high-demand sectors like oil and gas, power generation, and infrastructure.

Overview

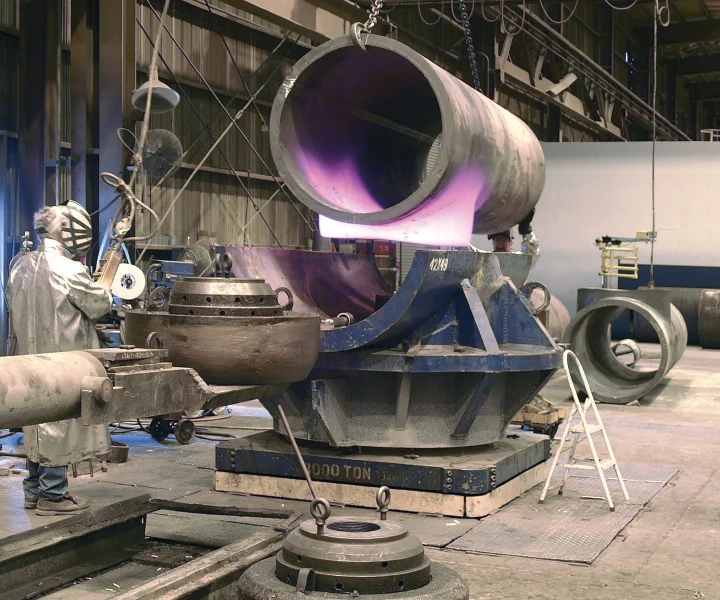

MANUFACTURING PROCESS

Taylor Forge manufactures it’s extruded headers using dyes it’s developed over 75 years of experience. With the ability to pull multiple holes on a single cylinder from as small as 1” up to 72”. The process is considered a “closed” die extrusion due to the use of an inner and outer dye. The extrusion process uses the heated of a pilot hole within a cylinder and an external and internal die to “pull” or “extrude” a smooth contoured hole from the excess pressure wall plate within the cylinder run/main line. This allows for very controlled and repeatable outlet creation that protects against deformation. Utilizing in-house ovens, Taylor Forge can quench and temper, normalize, and anneal fittings to the various final hardness and yields necessary for the complex sites they’re needed.

EXTRUDED MANIFOLDS AT YOUR FACILTIY

The extruded header or manifold solution is widely used in compressor stations, gas plants, treater units, and refining/plastics applications worldwide. It is commonly chosen to eliminate welds in locations where radiography is difficult or impossible, and to provide connections that would otherwise require a reduction from a B16.9 tee. Typical applications include aftercooler manifolds at compressor stations, meter skids, heater systems, launchers and receivers, and other custom fittings that would otherwise require reducers.