While lead time does vary, the main considerations for estimating the time to build a Vortex system is mostly dictated by the operating conditions, design conditions plot space restrictions specified by the end user. These conditions as well as the metallurgical requirements dictate the material thickness and the overall size and weight of the system. Utilizing the savings from the vortex design and Taylor Forge’s ability to manufacturer vessels with high strength materials to the ASME Section VIII Division 2 code, can help you save money on your project.

Vortex Advantage

- While lead time does vary, the main consideration for estimating the time to build a Vortex system is the overall size of the unit. Pipe size units can be delivered fast and plate based units take a little longer. The general tips below will help you achieve savings from the vortex design and Taylor Forge’s ability to manufacturer vessels various high strength materials.

- Maintenance, none required. Choosing a vortex separator over one with a vane pack, mesh pad, or filter elements, eliminates the regular costs of these other units.

- Vortex can very efficiently deal with high flow turndowns.

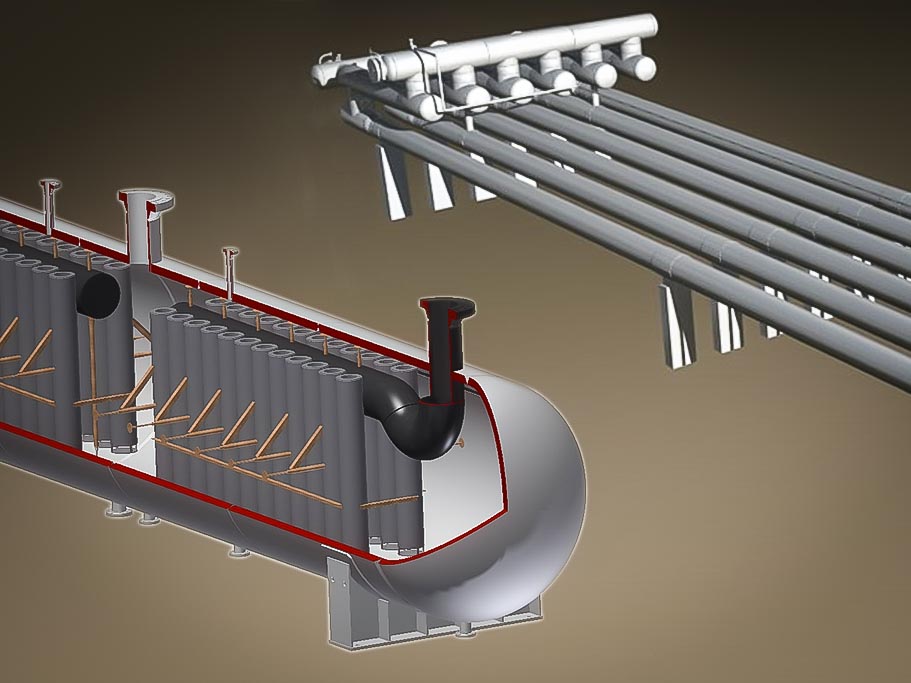

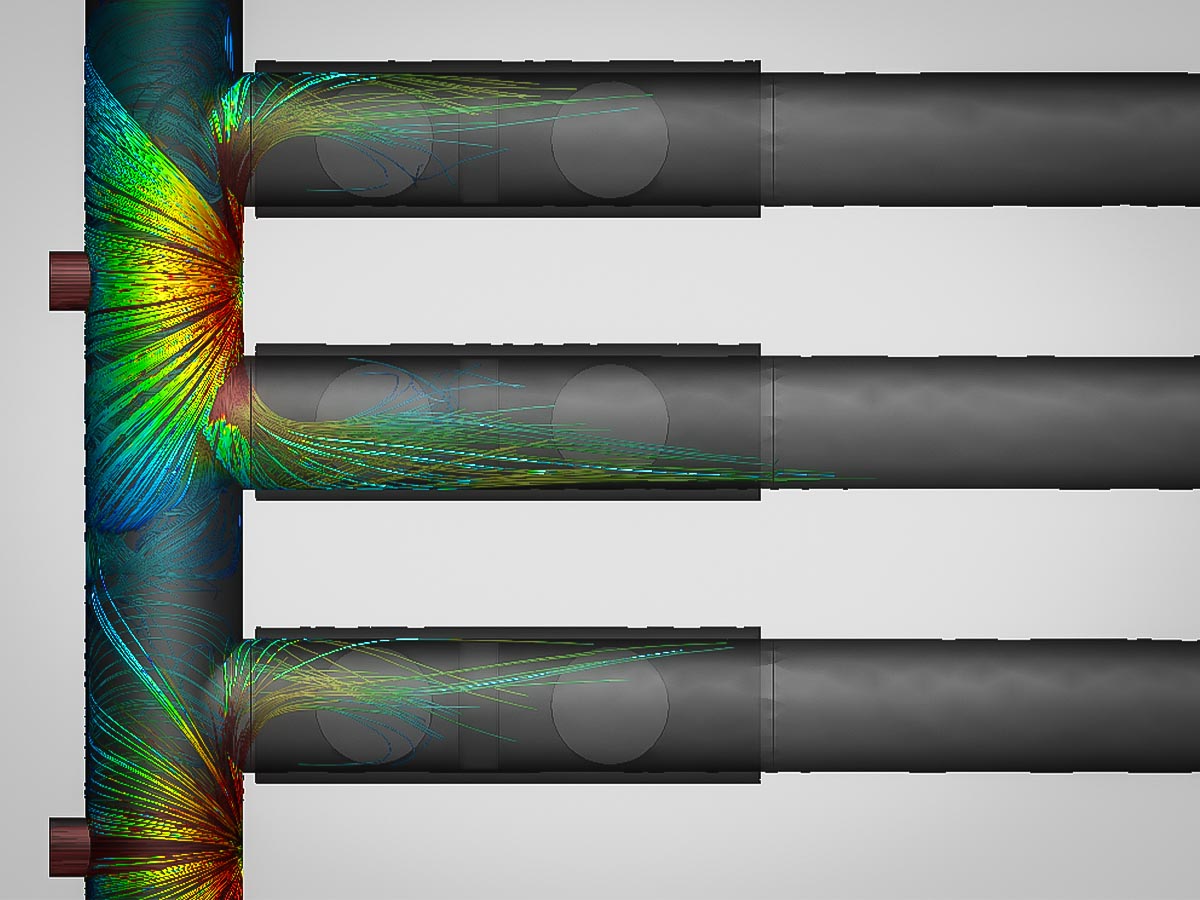

- When you have the need for significant gas flow and also liquid storage, vortex separation can shrink the vapor space required in your unit. This will allow for a smaller unit when compared to standard empty separation vessels.

- The Vortex Cluster design will achieve high efficiency separation (of 99.9% removal of solids down to ≥ 0.3 microns and 99.9% removal of free liquids down to ≥ 1micron). This should allow you to eliminate additional downstream separators (filters, separation tanks, etc). This is also applicable for slug catcher and other storage vessels where the Vortex separation allows for the reduction in # or required pieces of equipment.

- Design flexibility, units can be oriented both vertically and horizontally.

- Fabricated to the ASME Section VIII Division 2 code to reduce thickness, weight, and price.

Size

- For units with ODs <24” standard pipe will be utilized for the main shell and boot (if necessary). These units will be available with fast lead times, <20weeks

- For units with IDs >24” it all depends on the lead-time for the plate from the mill. For most pressures plate can be procured ‘off the shelf’ or from in stock material, in these cases deliveries can still be achieved in <26 weeks.

- For larger vessels >72” and corresponding higher pressures, the amount of plate required will likely require a mill run. When a mill run is required, deliveries can be as much as 42 weeks for the vessel.

Pressure

- For pressures <1440psig (600#), plate will likely be available in stock. An ASME Section VIII Division 1 vessel will be acceptable and economical.

- For pressures >1440psig (900# and greater), plate will require a mill run.

- As the pressure rises, you should be considering an ASME Section VIII Division 2 Vessel. Division 2, because of additional Testing and stress analysis, allows for the use of higher allowable stresses in the base material for your vessel. This means thinner plate and savings.

Other Technical Articles

As a leader in Slug Catcher design, here are some guidelines every engineer should know.

Choosing the type of Slug Catcher equipment for your next project? This breakdown will help guide your decision.

Understanding the separation methods for your finger-type slug catcher.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.