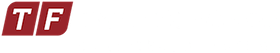

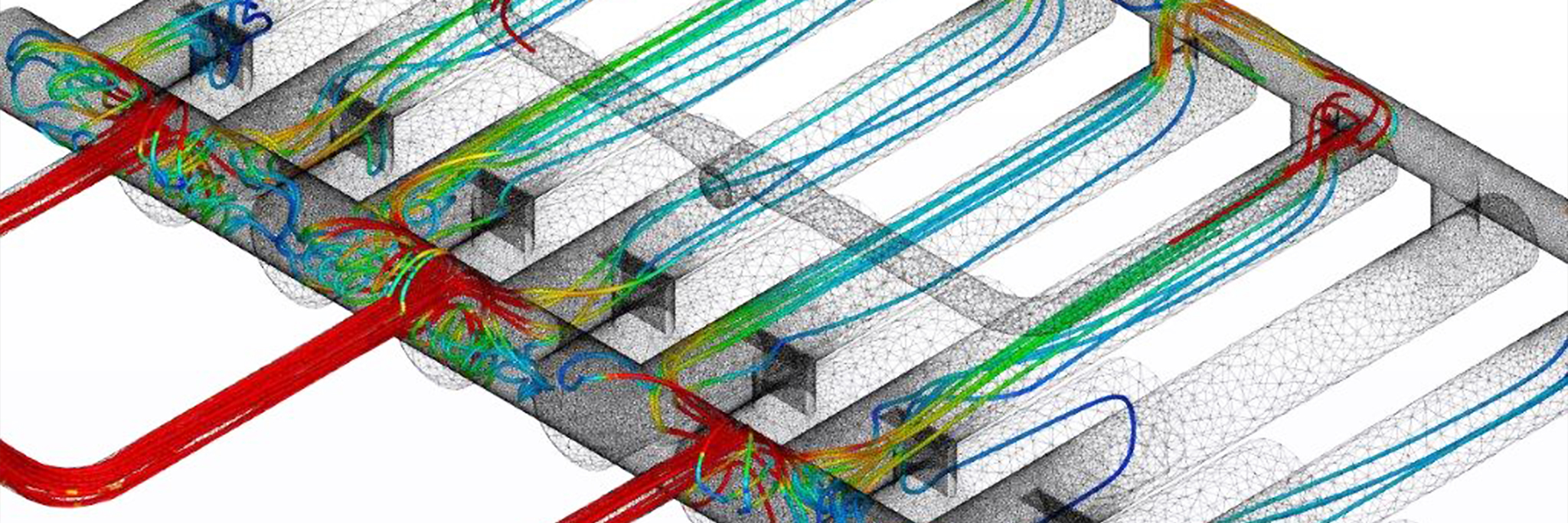

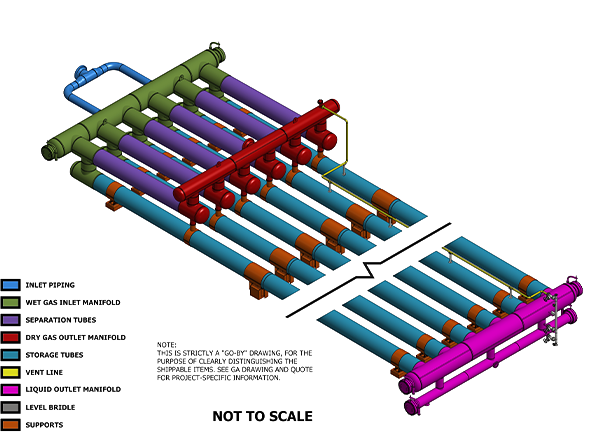

Distribution is a critical design aspect for finger slug catchers. Even distribution amongst the fingers allows for proper separation and helps to avoid carryover. Below are some of the design aspects we recommend considering for your slug catcher design.

Even Distribution

Finger type slug catchers achieve their best separation in even numbers: 4,6,8,10,12 fingers. Odd number slug catchers have a propensity to have uneven distribution, therefore, symmetry is critical. Upset conditions will occur, stratified flow is not always possible, and it’s in these conditions that your slug catcher must be designed to help slow down and equally distribute the flow to avoid flooding fingers. Flooding fingers is a very common issue that leads to flooded vent and balance lines and eventually carryover.

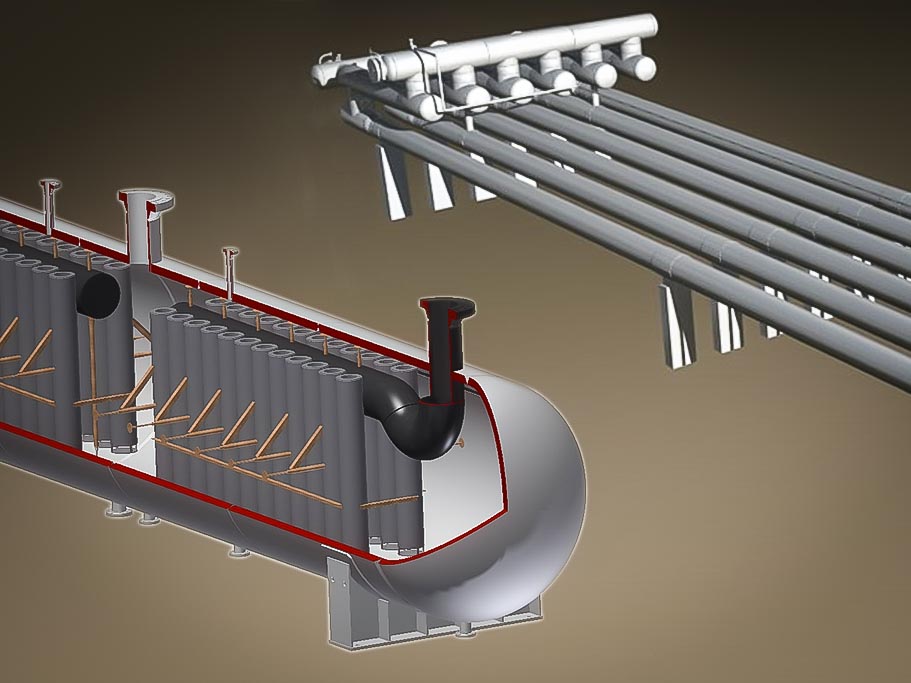

Cross Manifolds

We utilize cross manifolds: wet gas inlet, gas outlet, liquid header, and liquid outlet, to achieve balance across our entire slug catcher. That means we utilize a full sized header to balance our flows at the inlet and both outlets (gas and liquid). Not just a 10” equalization line. In upset conditions (a pigging event), if flooding occurs, that 10” line will also flood, rendering it incapable of serving its purpose. Without a cross manifold, the fluids have no way of balancing and will then carryover out of your gas outlet.

The cross manifolds balance the liquids at both the inlet and outlet. Hence, if for some reason flow is turbulent and a particular finger fills first, the back end of the slug catcher will redistribute the flow.

5D Inlets and Outlets

We recommend at a minimum 5 diameter lengths of straight pipe run prior to entering the slug catcher. This simple but imperative design note helps the unit achieve laminar and stratified flow entering the slug catcher. The smooth flow better ensures even distribution at the inlet of the fingers.

Downcomers

A finger slug catcher’s primary goal is separate bulk liquids from the process stream. In order to accomplish this, all designs use some form of a riser or downcomer to separate bulk liquid away from the gas. We’ve found an undersized downcomer or riser can quickly form a choke point in the slug catcher’s system and lead to significant carryover.

Our design utilizes the downcomer for both liquid separation to the fingers and also vapor return up to the gas outlet. We size our downcomer to handle the volume at a worst case scenario, to handle this flow without choking. Please contact us for more explanation.

Other Technical Articles

Choosing the type of Slug Catcher equipment for your next project? This breakdown will help guide your decision.

As a leader in Slug Catcher design, here are some guidelines every engineer should know.

So you’re on a budget? Check out these 5 tips to save money on your next Slug Catcher Project.

WHY US

Taylor Forge Engineered Systems

has continued the reputation of traditionally dependable products

to a variety of industries.

Integrity

We don’t compromise our practices and we won’t cut corners.